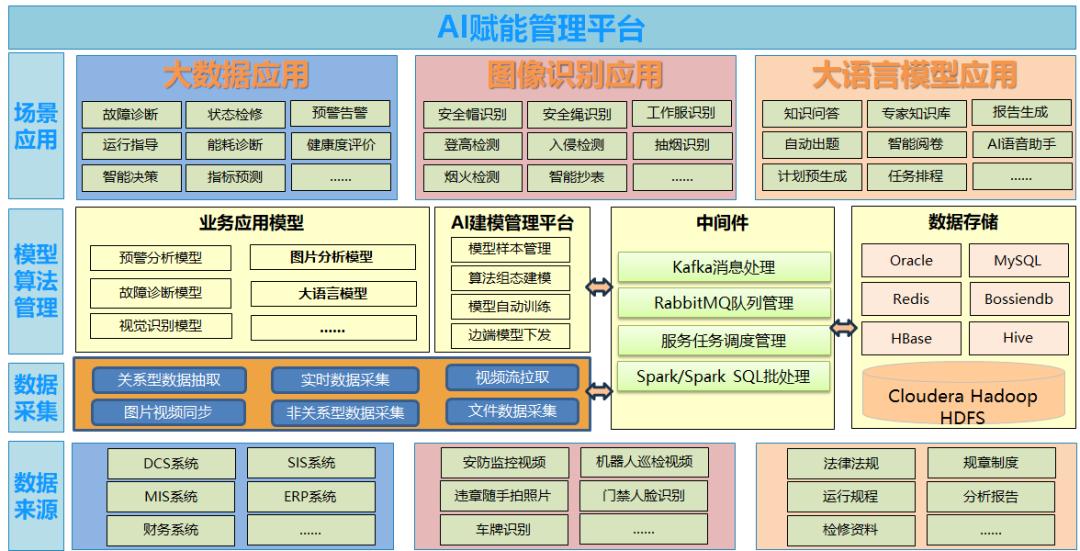

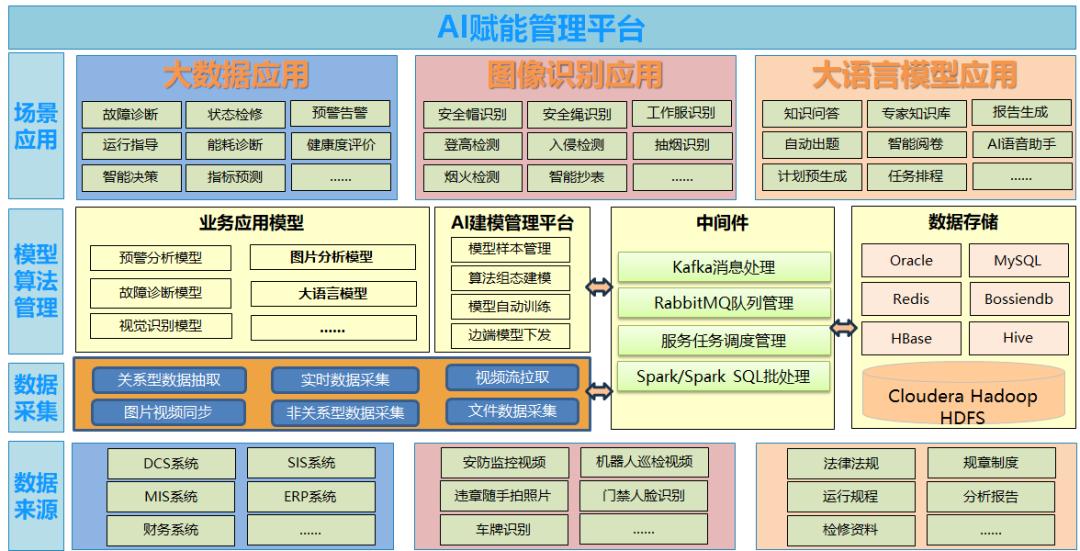

LOGE-AI is closely integrated with the development trend of smart power plants. It uses AI technologies such as computer vision, deep learning, and neural networks with its powerful data processing and learning capabilities to solve the following problems in the construction of smart power plants: fragmentation of business perception, extensiveness of safety and supervision, difficulty in optimizing production processes, diagnosis of a large number of equipment failures, challenges in stable equipment operation, difficulties in continuous optimization of asset efficiency, high risks and long cycles in application development. It provides a new way to solve these problems. We have developed our own AI empowerment management platform, extracted data such as security monitoring videos, robot inspection videos, and photos of violations, analyzed environmental equipment anomalies and personnel behavior through cloud computing and GPU computing resource pools, and actively and intelligently identified on-site environmental anomalies, equipment anomalies, and on-site personnel behavior and clothing, supporting a wealth of algorithm management, equipment management, and alarm management functions.

Application scenario 1: Realize equipment safety monitoring and status analysis through online video inspection

Use existing surveillance cameras to conduct regular online video inspections of video surveillance areas. Analyze the real-time surveillance video of the equipment to automatically identify the equipment status, such as equipment leakage, indicator light status, and pressure plate opening and closing status. Equipment safety monitoring includes the identification and monitoring of equipment status, equipment appearance, equipment temperature, and equipment accessories, and automatically alarms when abnormalities occur. Focus on monitoring key areas and environmental equipment, and the alarm details can be played back for historical tracing.

Application scenario 2: Identify and analyze personnel safety status based on image recognition algorithms

Based on AI image recognition algorithm, the personnel identification and analysis function is realized, and real-time intelligent identification and alarm are carried out for illegal intrusion, not wearing a helmet, not wearing a safety belt correctly, not wearing work clothes, smoking, playing with mobile phones and other illegal behaviors, as well as sudden abnormal situations involving personnel safety such as personnel falling. For example: if someone enters the production site without wearing a helmet as required, the system will analyze the captured images in real time and alarm, and display the alarm information and pictures in the management background.

Application scenario three: Establish a big data analysis and diagnosis model to automatically identify various degradation and fault conditions

By using big data analysis technology and focusing on the characteristics of massive data, a big data analysis and diagnosis model is established to automatically identify various types of degradation, failures, and uneconomic conditions, and achieve the effects of operation monitoring, equipment monitoring, and energy-saving monitoring. Through reliable data analysis and logical judgment, possible failures can be predicted and measures can be taken in advance to reduce the possibility of failures or mitigate the degree of harm caused by accidents.

Application scenario 4: Through the establishment of a large maintenance management model, the required information can be retrieved at any time during the maintenance operation

By establishing a large maintenance management model, the required relevant information or instruction manuals can be retrieved at any time during the maintenance operation. The knowledge base can integrate various drawings, audio and video materials, and can be retrieved and viewed at any time through voice interaction, and supports functions such as zooming in, zooming out, and locking the screen. Standard operating procedures can be integrated. During daily standard operations, employees can use operating instructions for real-time operating guidance to ensure work efficiency and accuracy.

Application scenario 5: Based on the expert knowledge base and guided by the inference engine, an intelligent auxiliary monitoring platform is formed

The intelligent auxiliary monitoring platform is based on the expert system, using qualitative analysis and quantitative calculation, which can effectively avoid the interference of useless alarm information from DCS, accurately and quickly locate abnormal parameters, analyze the causes of abnormalities, and give treatment opinions. Based on the expert knowledge base and guided by the inference engine, an intelligent auxiliary monitoring platform with certain versatility is formed. The expert knowledge base is created based on equipment design data and expert knowledge and experience. Through the human-computer interaction mode, the experience of personnel is input into the computer, so that the expert knowledge base is continuously optimized and updated to improve the diagnostic accuracy of the expert system.

Application scenario 6: Prevent misoperation through the integration of AI video recognition, QR code, smart two-ticket and other technical applications

Through the integration of technologies such as AI video recognition, QR code, access control, real-time voice communication, and remote assistance, the operation process permission and end time are used as time elements, and the equipment positioning information is used as the space element to realize the overall operation process control of the operation ticket, real-time on-site recording and video recording, real-time audio and video feedback, personnel and ticket information confirmation to prevent personnel from being in place, QR code location confirmation to prevent misoperation, access control management to prevent accidental entry into the distribution room, electronic screen reminders of operation risks, real-time voice communication between on-site operators and background coordinators, remote assistance, operation content synchronization and analysis instructions to prevent the occurrence of misoperation.

Power production operations involve a large amount of diverse and specialized knowledge. The LOGE-AI empowerment management platform starts from promoting data business integration, mining the value of massive data, driving business optimization and upgrading, etc., to solve problems such as scattered knowledge, poor inheritance and lack of knowledge. It uses big data and big model technology to build a unified knowledge carrier. This carrier takes natural language interaction as its core, provides a powerful knowledge service engine for production operations, and ensures the effective application, sharing and transmission of knowledge.

EN

EN

ZH

ZH